NEW PRODUCTS: THHN AND THWN-2 . CIVIL WIRE

- 04:47, 12/06/2023

- 5012

In addition to the traditional products that CADIVI is providing, grasping the market's demand towards a product line with more outstanding features, safety and environmental friendliness, CADIVI has researched and released a product line. THHN and THWN-2 single-core residential cords, which are designed and manufactured in accordance with safety standards, meet the stringent requirements of UL 83 and comply with design code requirements, installation of the NEC-NFPA electrical network. Helping customers have more choices in the domestic market as well as exporting to foreign markets.

The electrical cable market in the US along with some countries is limited by technical barriers established by UL (Underwriters Laboratories) and NEC-NFPA (National Electric Code). UL is an independent organization responsible for certifying the safety of products circulating in the United States. NEC-NFPA is the author of the set of safety rules for electrical network construction and fire safety applied in the US.

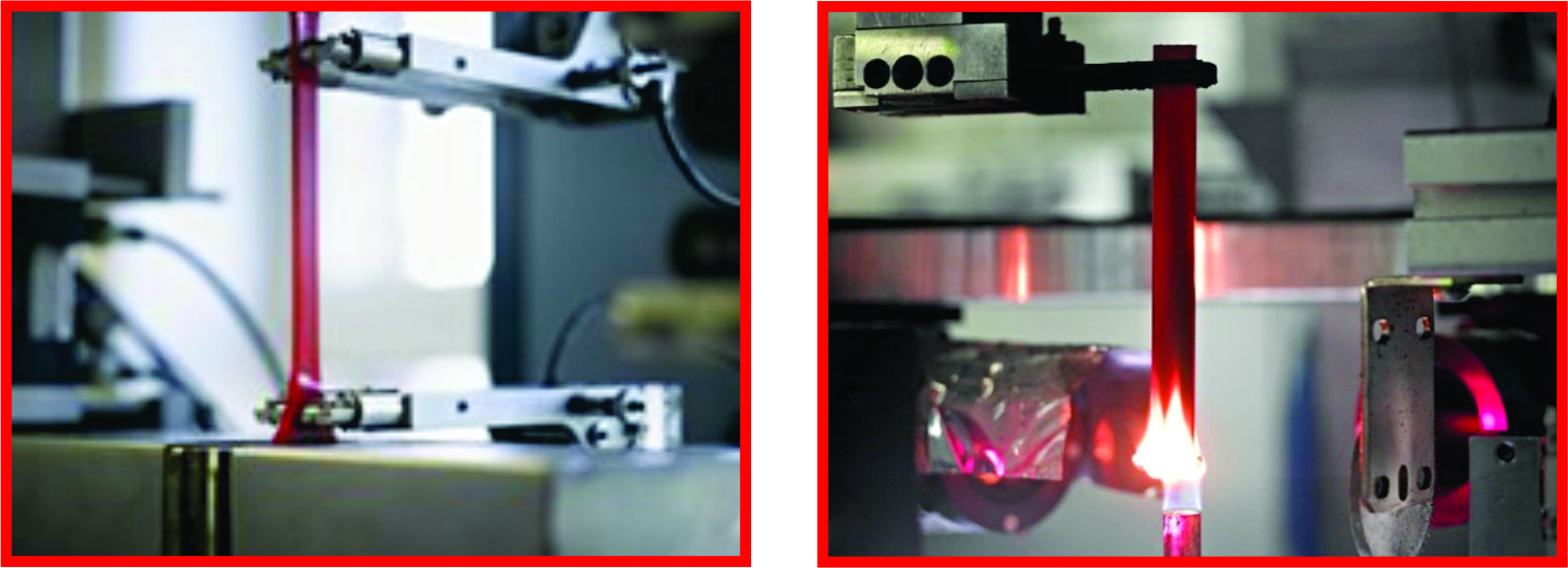

UL and NEC-NFPA have established a series of rigorous safety standards and regulations for electrical cables, including testing for fire resistance, flame retardant, load capacity, heat resistance, water resistance and many more. Other requirements. These standards and regulations ensure that electrical cable products meet US safety requirements.

Not only products meet UL requirements, but CADIVI electrical cable manufacturers must also meet the requirements of production facilities and quality control laboratories according to US standards to ensure quality consistency. for product.

Both THHN and THWN-2 have good heat resistance properties and are capable of working in harsh environments:

THHN (Thermoplastic High Heat-resistant Nylon-coated): designed with a maximum conductor working temperature of up to 90oC, installed in a dry place.

THWN-2 (Thermoplastic Heat and Water-resistant Nylon-coated): designed with a maximum conductor working temperature of up to 90oC, installed in wet, wet as well as dry places.

THWN-2 is the upgraded specification of THWN product code (maximum conductor working temperature up to 75oC, can be installed in wet, wet as well as dry places).

|

OTHER FEATURES AND CHARACTERISTICS OF THESE PRODUCTS: Special PVC coated insulators with improved specification make them operate at high temperature class up to 90oC compared to conventional PVC wire products which only operate at temperature class up to 70oC-75oC . |

|

AREA OF APPLICATION OF THHN, THWN-2 INCLUDES: Installation of low voltage electrical networks in walls, ceilings, floors of civil electrical systems and industrial electrical systems, grounding the electrical system. |

THHN and THWN-2 products are often manufactured with a variety of conductor cross-sections to suit the needs of each application. The conductors are soft annealed pure copper, flexible conductor type (class 5) or concentrically twisted conductor (class 2) and solid single-strand conductor (class 1).

Collectively, the advantages of THHN and THWN-2 can be summarized as follows.

![[Most Recent Quotes from www.kitco.com]](http://www.kitconet.com/charts/metals/base/copper-d.gif)

![[Most Recent Quotes from www.kitco.com]](http://www.kitconet.com/charts/metals/base/nickel-d.gif)

![[Most Recent Quotes from www.kitco.com]](http://www.kitconet.com/charts/metals/base/aluminum-d.gif)

![[Most Recent Quotes from www.kitco.com]](http://www.kitconet.com/charts/metals/base/zinc-d.gif)

![[Most Recent Quotes from www.kitco.com]](http://www.kitconet.com/charts/metals/base/lead-d.gif)